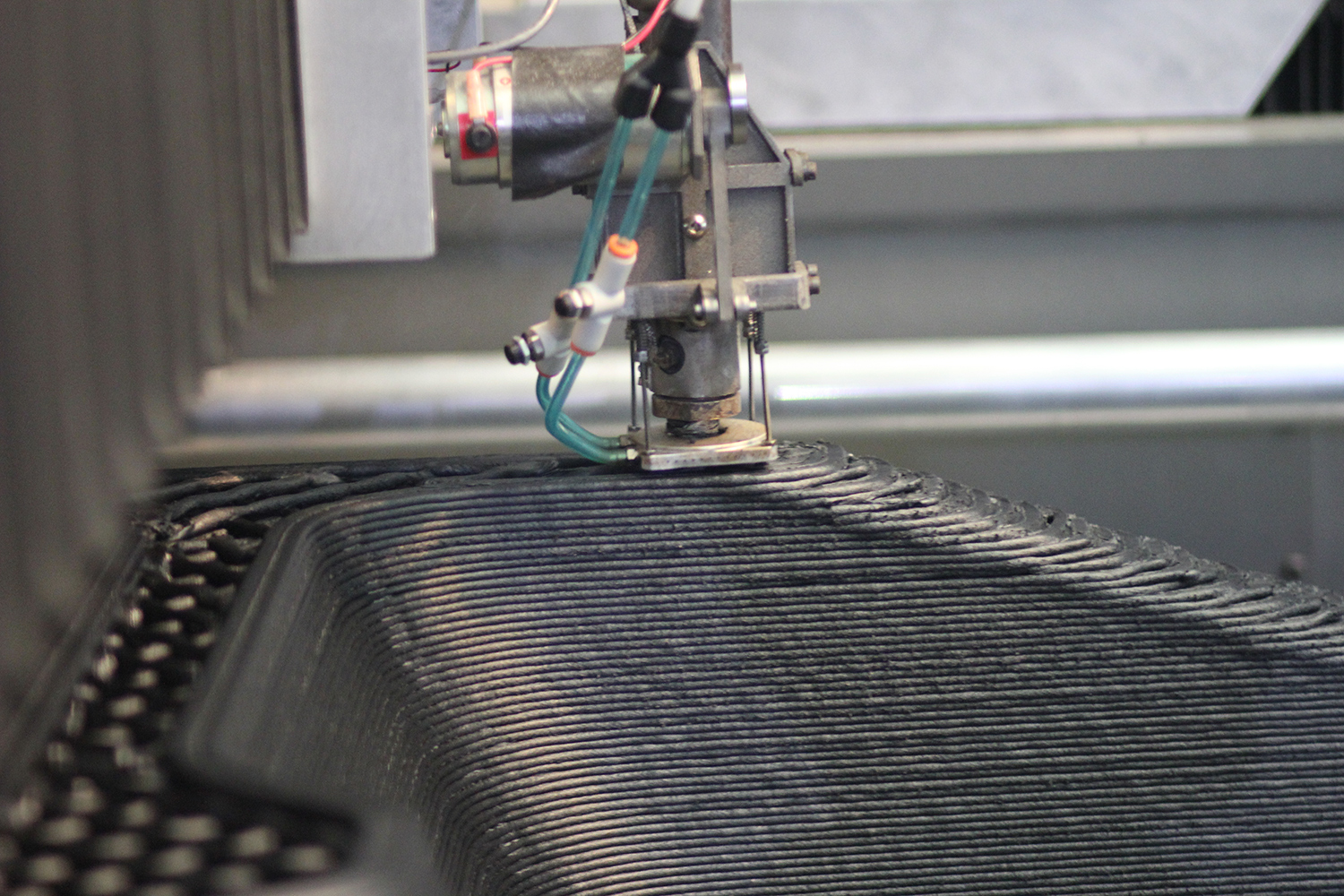

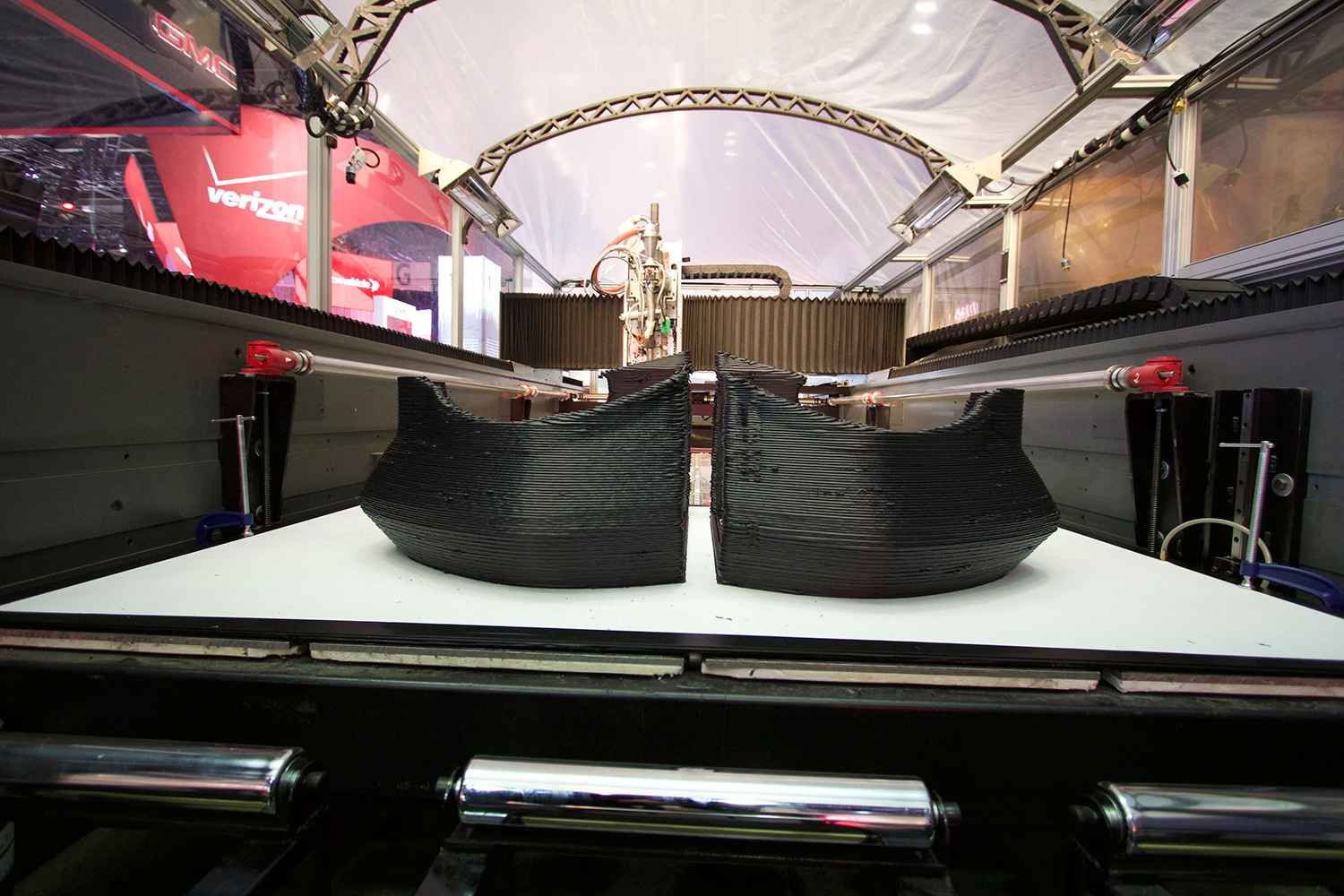

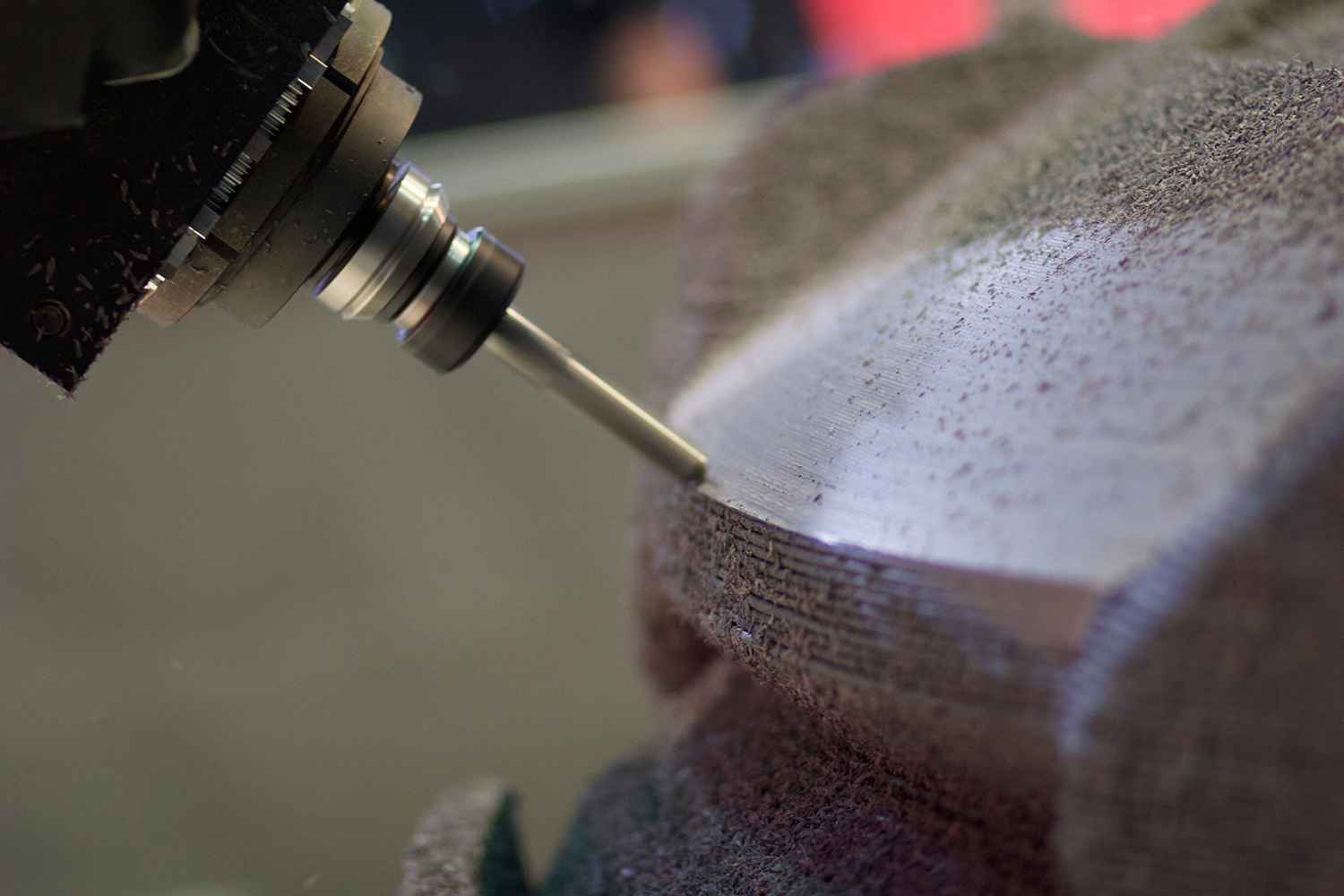

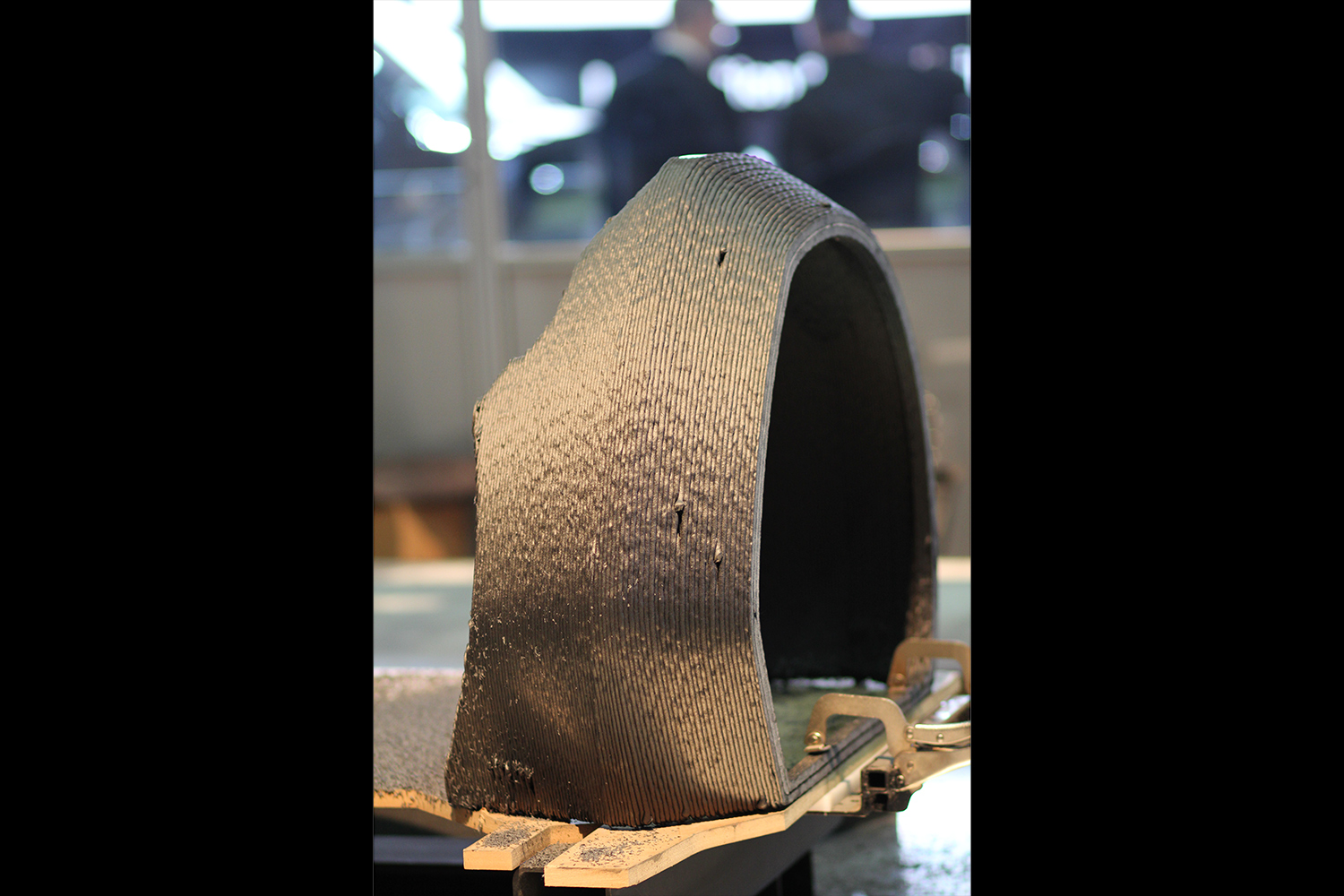

The company selected the Swim design submitted by Ken Lo of Portland, Oregon in July of this year and built a prototype version of the car in September. Almost 75 percent of the car is 3D printed using a blend of 80 percent ABS plastic and 20 percent carbon fiber. And these parts, which include the body panels and other aesthetic components, are customizable, allowing owners to create cars that share the same underlying power train, but look radically different.

Local Motors has a lot of experience building cars, even 3D-printed ones. The company made a name for itself with the Rally Fighter, a crowd-sourced off-road vehicle that looks someone bolted a Camaro body on the frame of a jacked-up Ford F150. With the success of the the Rally Fighter under its belt, Local Motors then did a 360 and started pursuing the concept of 3D-printed cars.

At the 2014 International Manufacturing Technology Show in Chicago and this year’s Detroit Auto Show, the company 3D printed a version of its full-sized sporty Strati model. The Strati was built using an electric power train sourced from a Renault Twizya and required only 40 total parts for assembly. It was printed on the show floor in approximately 44 hours.

While the Strati served as a demonstration car, the LM3D Swim will be the first 3D-printed car to hit the highways. Local Motors will begin accepting deposits for the LM3D via a crowdfunding campaign that is expected to open some time in the second quarter of 2016. The company is on track to have crash testing and all other safety certifications completed by the end of 2016, when it will make the car available publicly via retail channels. Once production begins, the company has the capacity to produce up to 2,400 LM3D cars annually.