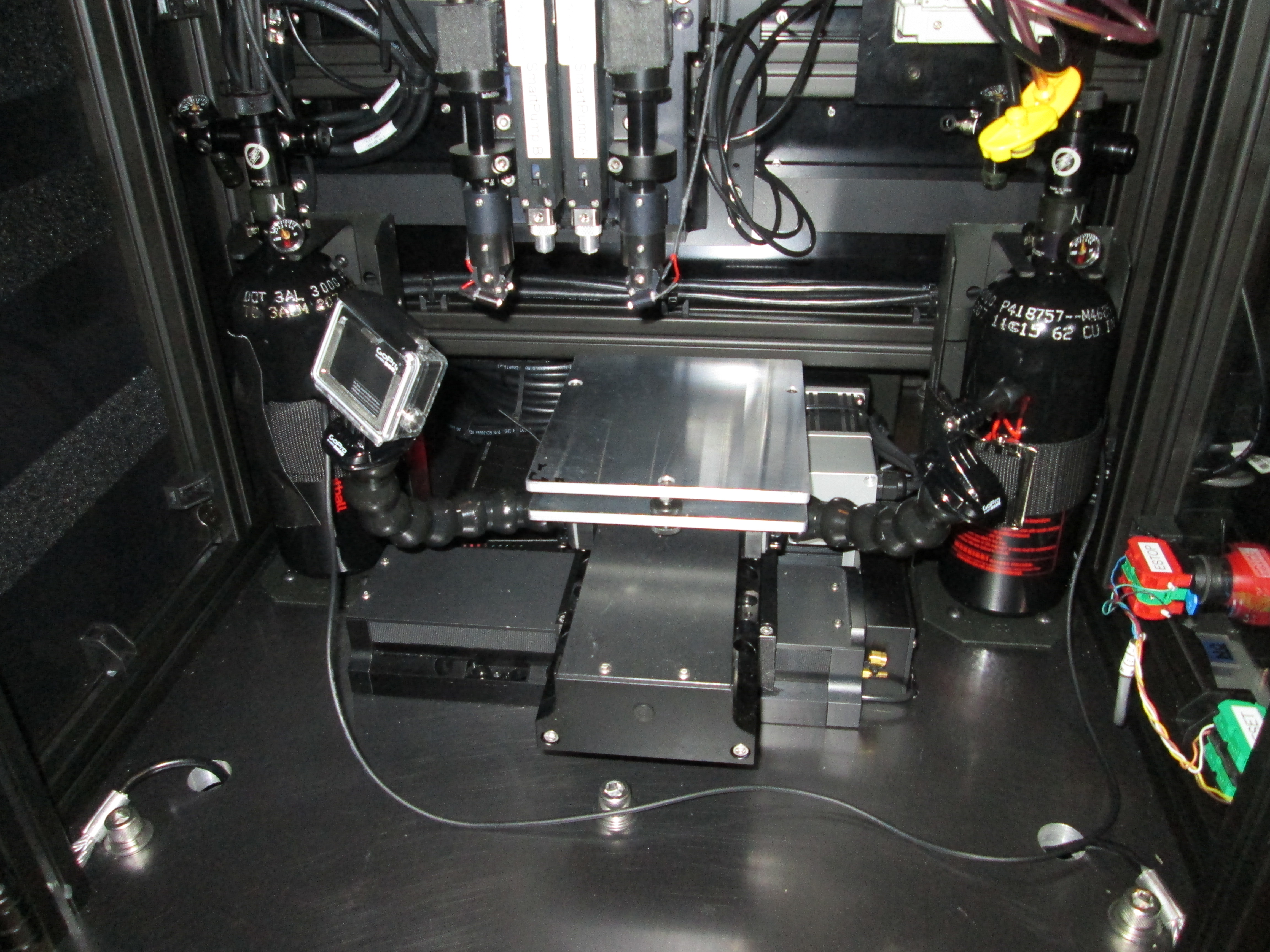

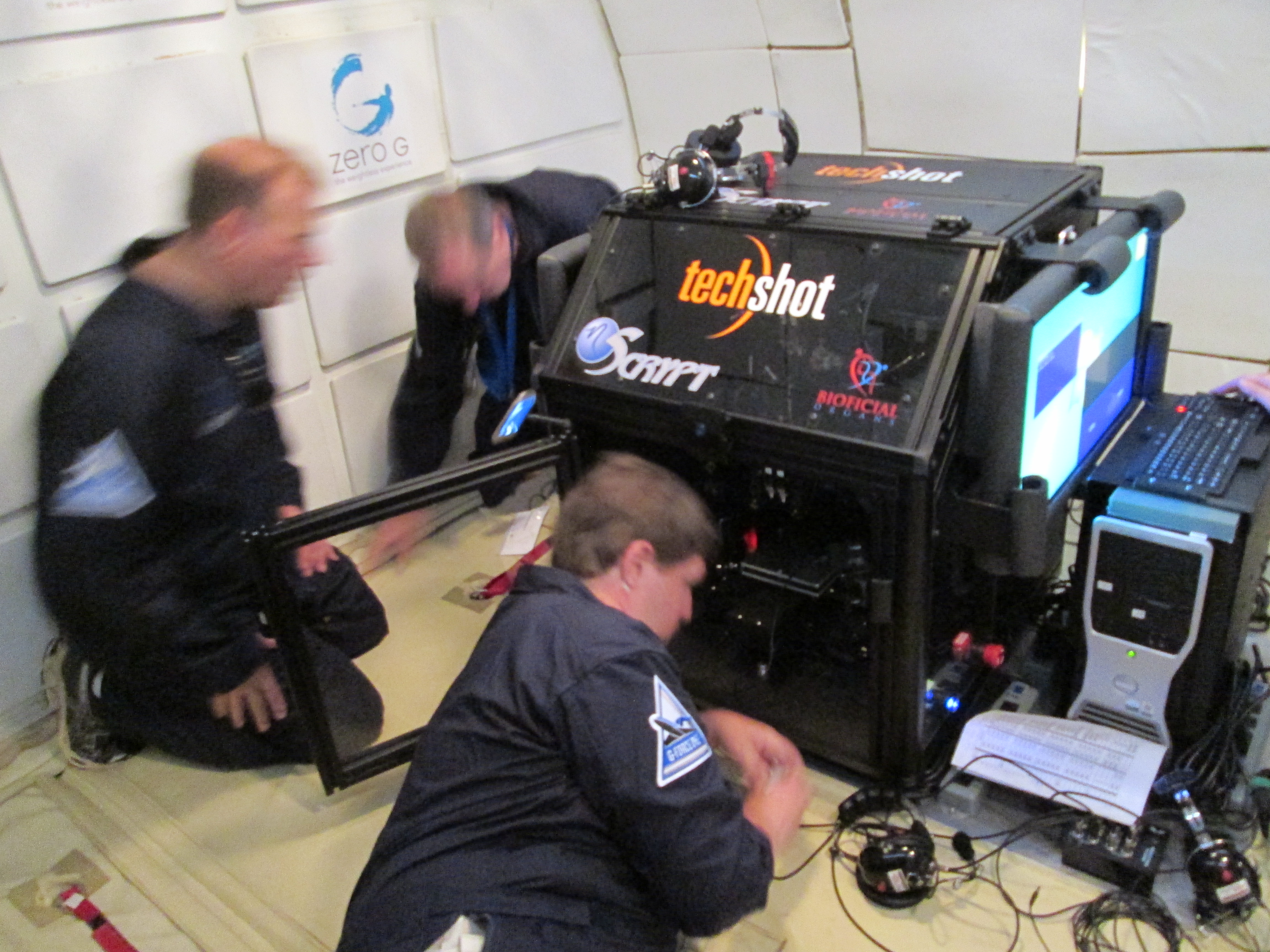

A collaboration between Techshot, bioprinting experts nScrypt and bio-ink innovators Bioficial Organs, the project saw researchers take to the skies in a Zero Gravity Corporation aircraft — the only commercial company in the U.S. to offer weightless flights — in order to test out their prototype printer.

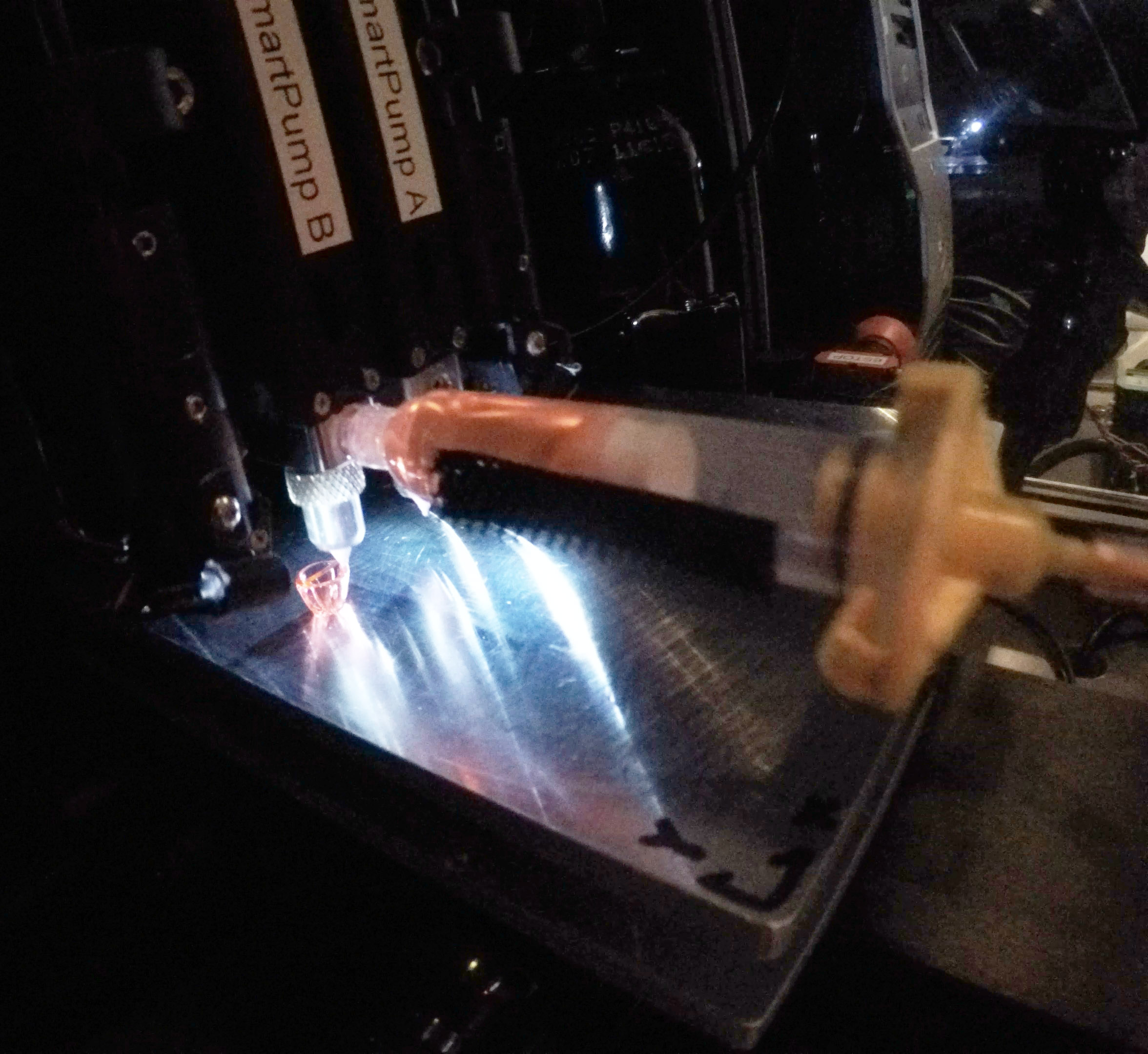

“We were constrained by the timeframe of a weightless flight,” Eugene Boland, Techshot’s Chief Scientist, tells Digital Trends. “On the Zero G aircraft, you’re only weightless for around 25-30 seconds at a time. As a result, we had to print fairly small structures — just to give us an understanding of how the printer works. While our eventual goal is to print an entire human heart, in this case it was more a neonatal-size structure, around the size of the end joint on your pinkie finger.”

Nonetheless, the mission was a rousing success and data gathered from it will now be used to design and build a smaller, more robust 3D bioprinter — which could be found printing organs on board the International Space Station as soon as 2018.

But aside from from the whole “crazy science” side of things, is there actually a sensible reason why 3D printing hearts in space may be a good idea? Actually, yes.

“3D printers aren’t good at printing gaps,” Boland continues. “They’re good at solid things, not hollow things. That makes it very difficult to print a heart in an environment like Earth where you have gravity, because the organ collapses in on itself. But if you go to space and take gravity out of the equation, you don’t have those same problems. It makes the possibility of this kind of bioprinting more feasible. And you could potentially save many, many lives as a result — since currently tens of thousands of people on the heart transplant list die each year. That’s where we envision this technology going.”

Color us convinced!