Robots are taking over car factories around the world, but in Sant’Agata Bolognese, Italy, Lamborghini is moving in the opposite direction.

Lamborghini is known across the world for its cutting-edge design language and state-of-the-art car technology, but as we found out, the process of building a Lambo is less about futuristic robots than we thought. Instead, the luxury car maker uses time-honed (and human) craftsmanship techniques. Join us as we tour the company’s plant in Sant’Agata Bolognese, Italy, to discover how a Lamborghini is built.

Sant’Agata Bolognese is a small town located approximately 20 miles away from Bologna, and a stone’s throw from Maranello, where long-time rival Ferrari is based. While Maranello has been gradually transformed into a tourist-oriented Ferrari-land of sorts, Sant’Agata has remained authentic over the years. That’s not to say it doesn’t attract tourists, but there are very few indications that it’s home to one of the world’s best-known sports car manufacturers.

The Lamborghini family

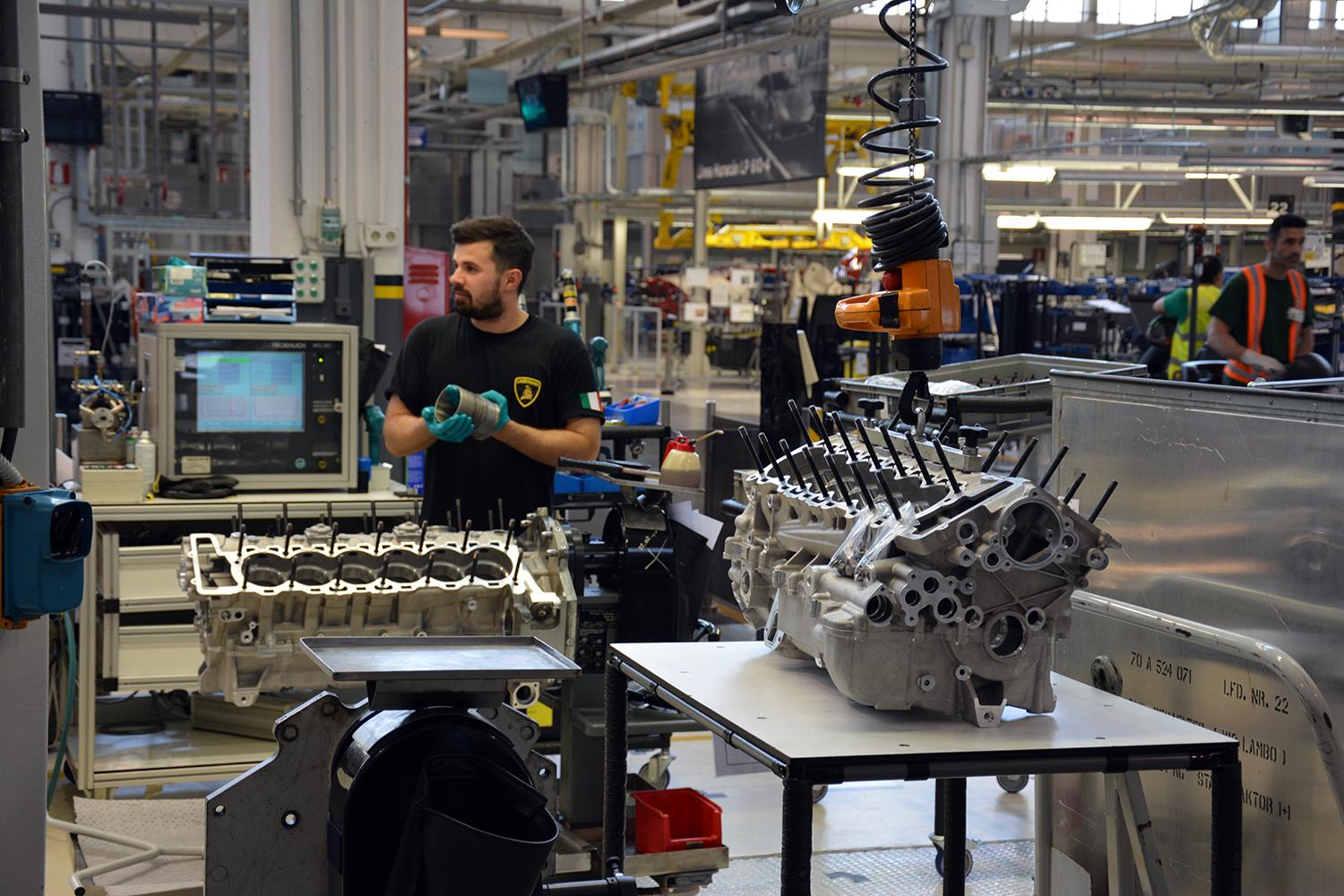

Lamborghini employees work from 8 a.m. to 5 p.m. from Monday to Friday, though the nearby carbon fiber plant operates three shifts in order to keep up with high demand. They are easily identifiable in Sant’Agata because they wear a black Lamborghini uniform that clearly indicates whether they’re assembly line workers, part of the factory’s logistics team, assigned to the prototype-building division, or someone else entirely.

Lamborghini trains all of its workers in-house, and employees are encouraged to move from station to station once they’ve mastered a certain skill. For example, a worker who assembles Huracán doors today could be fitting Aventador master cylinders in six months’ time. Once a worker has spent enough time on the factory floor to know Lamborghinis inside and out, he or she is eligible to become one of the company’s test drivers.

Precision through craftsmanship

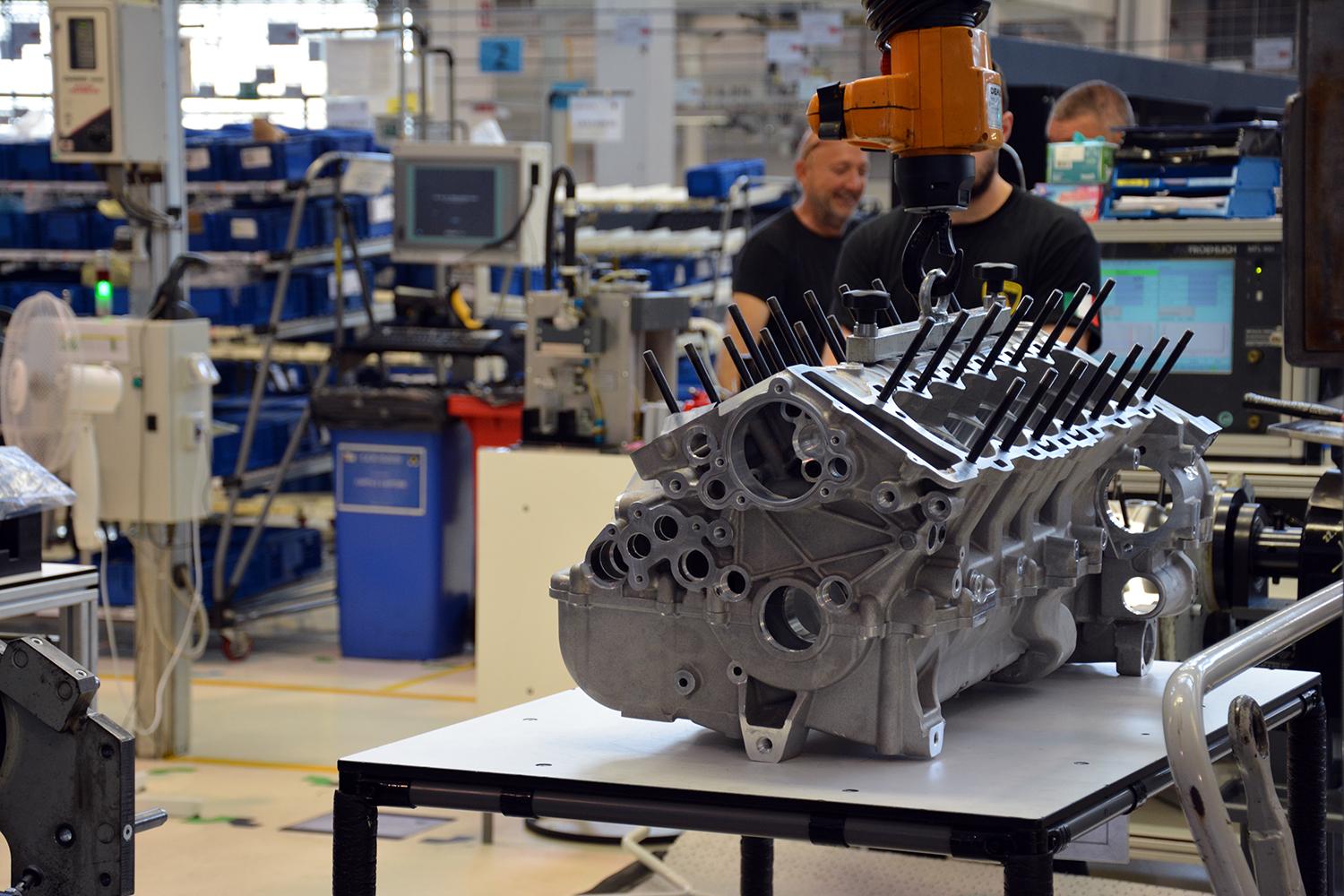

The most impressive part of touring the factory is to see the cars being assembled by hand. In fact, there are only two robots in the entire plant, a machine that drops the bare bodies onto the assembly line and a rotisserie that turns the cars upside down when needed. As a result, the factory is a lot quieter and more spacious than most people imagine it to be.

Every single Lamborghini built since 1963 has been tested on the picturesque roads of Sant’Agata.

Bodies and body panels arrive at the factory pre-painted and wrapped in a protective sheet of plastic. The Huracán is painted by parent company Audi in Neckarsulm, Germany, because it is built with more aluminum than carbon fiber, and the Aventador is painted by an Italian company called Imperiale that assigns a single worker to each car for the sake of consistency. The first order of business once the plastic sheet is removed is to immediately install thick covers to ensure the paint doesn’t get scratched or otherwise damaged as the car goes down the assembly line.

From start to finish, the Aventador spends 90 minutes at 12 different stations while the Huracán spends 40 minutes at 23 stations. Each one is built on a separate assembly line, and a screen located above each station keeps track of how long the car has been there for, which helps workers manage their time more efficiently.

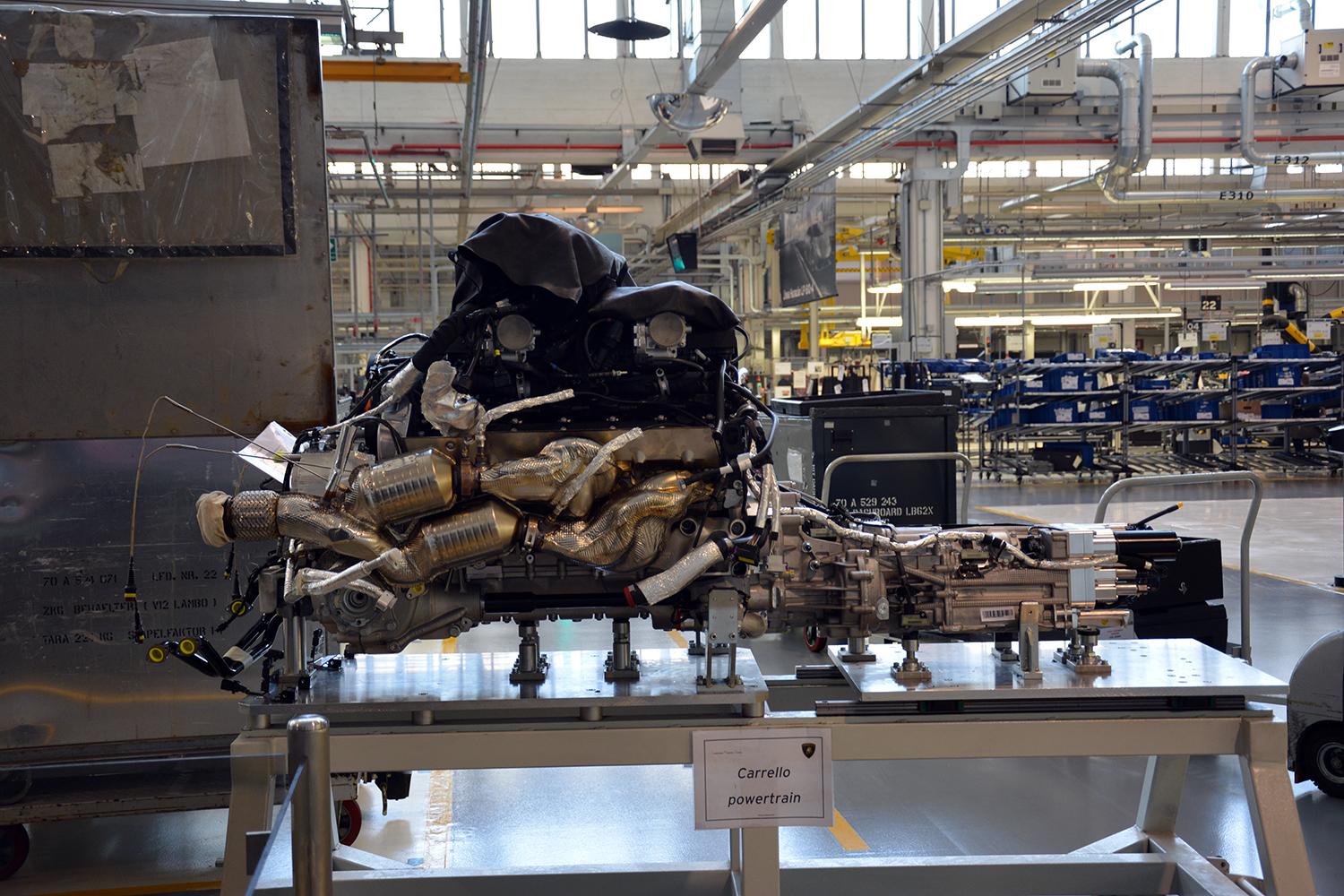

Lamborghini does not have a foundry so the high-revving 10- and 12-cylinder engines that power its cars are manufactured by outside suppliers and shipped to the factory where they are assembled — again, entirely by hand — and bench-tested. An upholstery shop makes every part of the interior including the seats, the knee bolsters and the door panels. At the far end of the shop, a special booth capable of replicating a wide array of different lighting conditions helps ensure the leather- and Alcantara-upholstered panels that come together to make up a specific car’s interior are the same color regardless of the amount of light it’s exposed to beforehand. Interior parts are only sent to the assembly line for installation once they have passed this test.

When a car is completed it has to go through three rounds of final testing before it is delivered to its lucky new owner. The first round involves using lasers and cameras to check that every part (including suspension-related bits and pieces and body panels) is precisely aligned. The second step consists of running the car on a dyno (a treadmill for vehicles) for 40 minutes at a top speed of 180 km/h (about 112 mph) to ensure all mechanical components are in working order. Finally, the third step is a full 20-to-30-mile test drive on public roads.

Tradition runs strong at Lamborghini, and every single car built in Sant’Agata since 1963 has been tested on the picturesque roads around the factory. In spite of that, locals of all ages continue to turn their heads every time a fire-breathing Raging Bull blasts by.