What Matzaridis has created through the digital magic of additive manufacturing is an accurate replica of an original Stradivarius violin, the Sunrise Stradivari — one of the incredibly expensive and rare master violins built by the Italian family Stradivari during the 17th and 18th centuries.

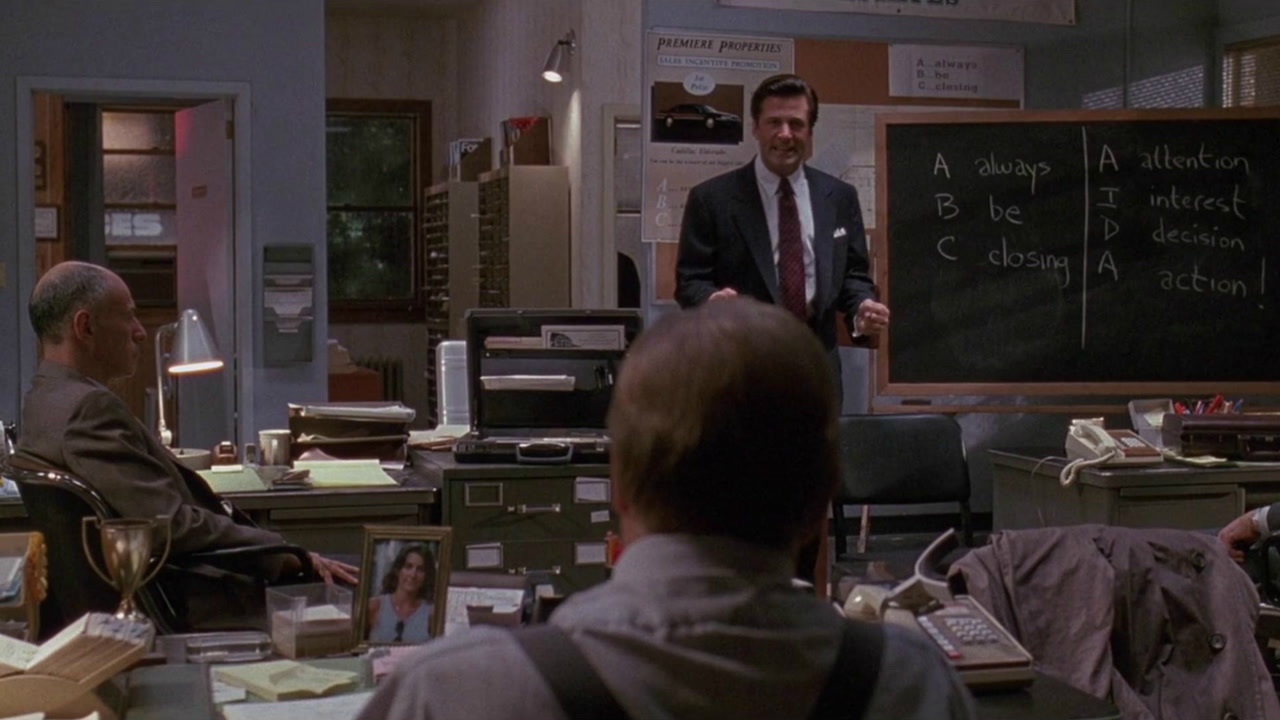

“ViolinoDigitale is essentially all about developing a specific ‘making’ process as an additional tool to better understand the sound mechanics of the best-sounding musical instruments out there,” Matzaridis told Digital Trends. “With 3D-printed violin replicas, anyone can have a small ‘taste’ of an old master instrument, without wearing out the original. 3D-printed violins can incorporate a fresh approach not only in instrument making, but also in acoustics research studies.”

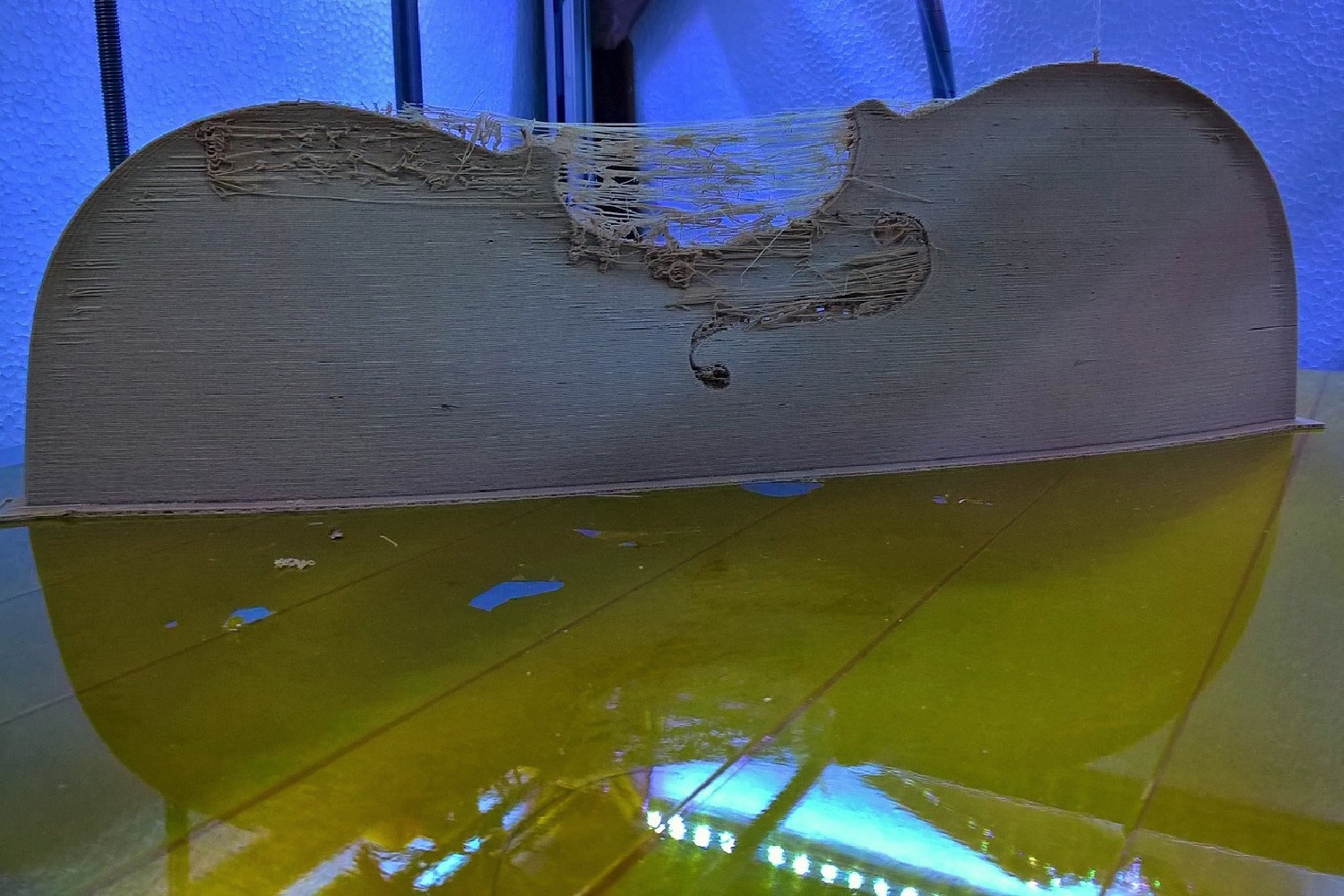

The amazing project took two years to create, and required the printing of more than 40 individual parts, as well as some impressive (and more old school) handcrafting. Many of the 3D-printed parts were printed using a wood filament. “The hardest overall challenge was to make a functional violin that does not deform or break under string tension, while sounding rich, fully natural and as least plastic as possible,” Matzaridis continued.

While we’ll admit to having something of a tin ear for the finer points of musicology, it seems that Matzaridis succeeded — since not only does the finished piece look like the instrument it’s meant to, Matzaridis says that it shares acoustic and tonal similarities with its inspiration.

Next up, Matzaridis said the plan is to build more violin replicas, along with larger acoustic instruments.

“Museums or research institutions can freely ask for their violins to be replicated for their museum indoor use, it is something that can be done as we speak,” Matzaridis concluded. “Also any organization or tech exhibition can invite me to speak and showcase my work in their premises. The violin is playable so they can even invite a violinist of their choice to play it so everyone can have a chance to hear it in person. I am currently constantly analyzing audio results, making comparative tests between printed and non-printed violins and preparing for academic journals’ proposals to publish those results.”