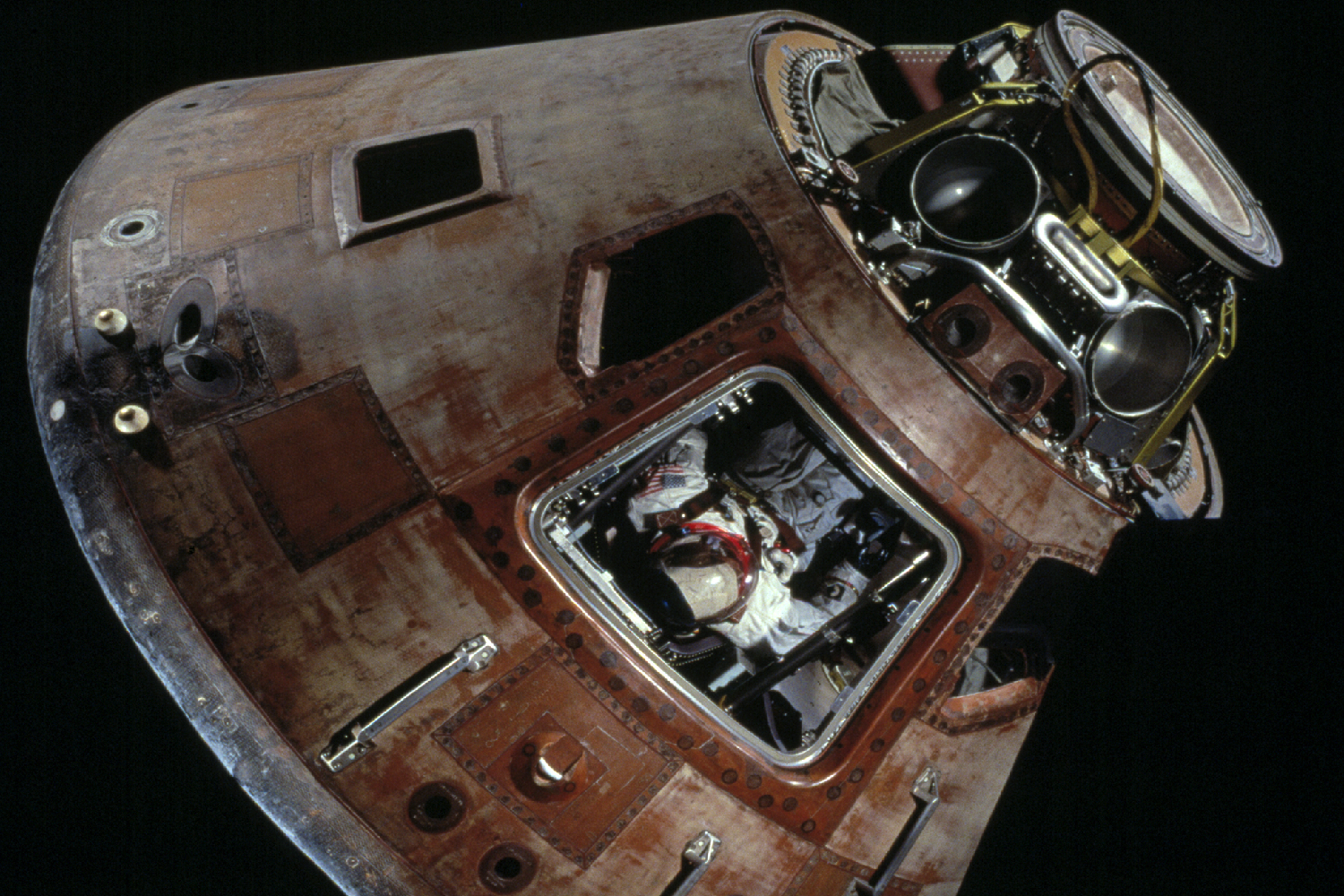

“The impetus for the project was that, for the first time in decades, the plastic covering which had sealed the command module away for decades was being taken off,” Vincent Rossi, senior 3D program officer at the Smithsonian’s Digitization Program Office, tells Digital Trends. “We were asked if we wanted to apply our 3D-scanning tools to it, and it just seemed an opportunity that was too good to pass up.”

As Rossi explains, the Smithsonian’s world-class collection covers an astonishing 154 million items — although there is only space for a miniscule 1 percent to be on display at any one time. “People think we’re just an exhibition center, but at our core we’re really all about research,” he continues. “What our team does is use 3D-scanning tools to create immensely detailed measurements about the objects we have across all of our different sites. That opens up all kinds of unique possibilities.”

What makes the Apollo 11 command module 3D data so cool is how it’s being used. People with 3D printers can download it and use it to print their own miniature versions of the module. “One person wanted to 3D print the command module multiple times and use them to replace all the knobs inside his pickup truck,” Rossi says. “A lot of teachers are using it as an education tool, to engage kids in this huge event in human history that many young students don’t really have a deep connection with, due to when they were born.”

But it’s not just available for the rarefied 3D printer owners out there. The data can also be viewed using a web browser, or even explored in immersive detail using a VR headset. In all, it’s an astonishing glimpse at the way that technology is opening up new ways to explore iconic artifacts.

“Finally, without having to be this librarian that won’t let you read the book because [they] are afraid you are going to ruin the binding, for the first time you can look as much as you want and explore the entirety of this priceless artifact,” said Allan Needell, Columbia’s curator at the National Air and Space Museum. “This is just a thrill to have access without the preservation concerns.”

In other words, it’s one small step for 3D scanning, but one very exciting leap for all mankind!