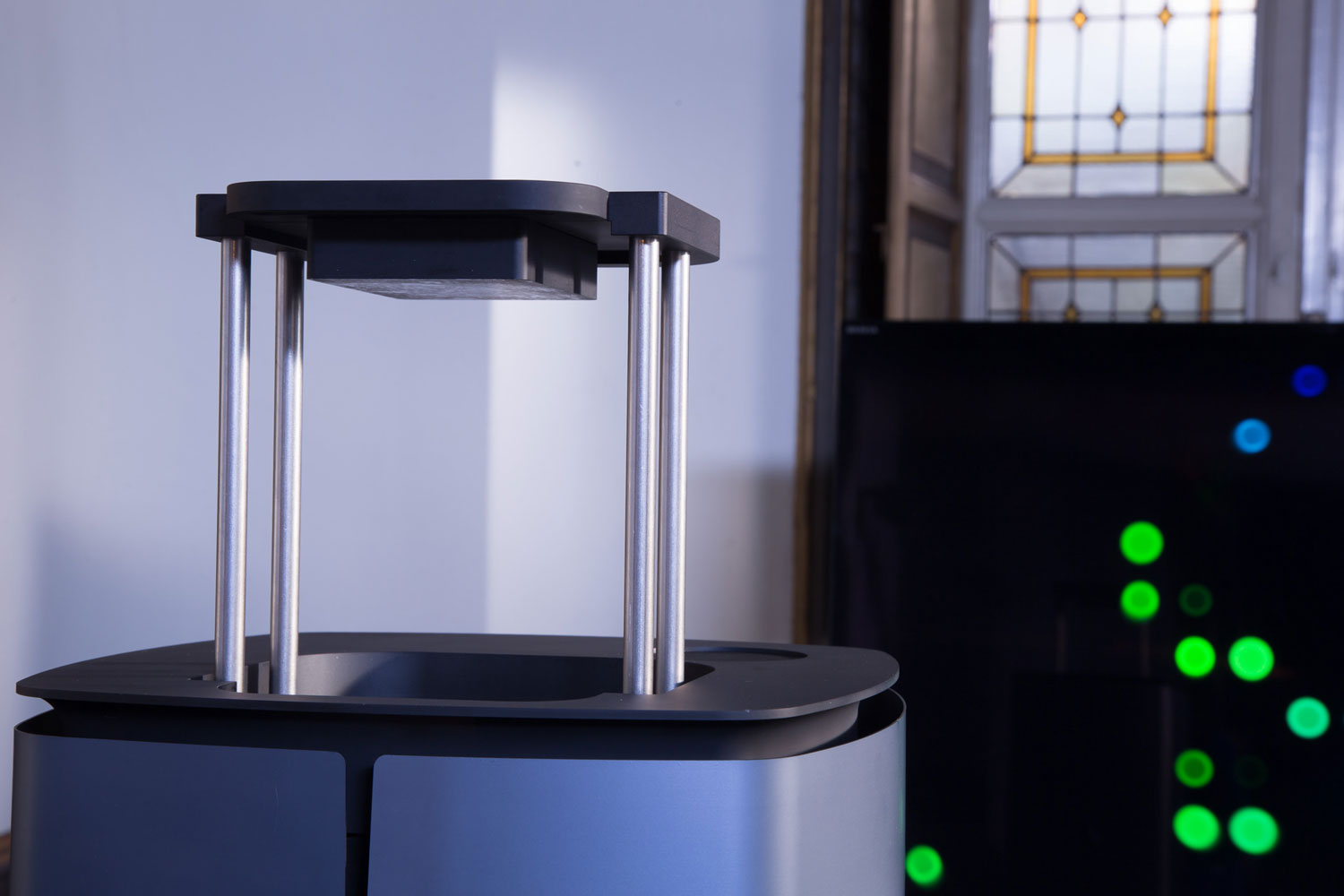

At first glance, the NX1 appears to operate just like a stereolithography printer. Instead of melting plastic to create objects layer by layer, it uses a laser projection system to “grow” objects out of a pool of UV-curable resin. This technique has been in use for years now, but the NX1 employs a clever chemical trick to supercharge the process and produce prints at a considerably faster rate.

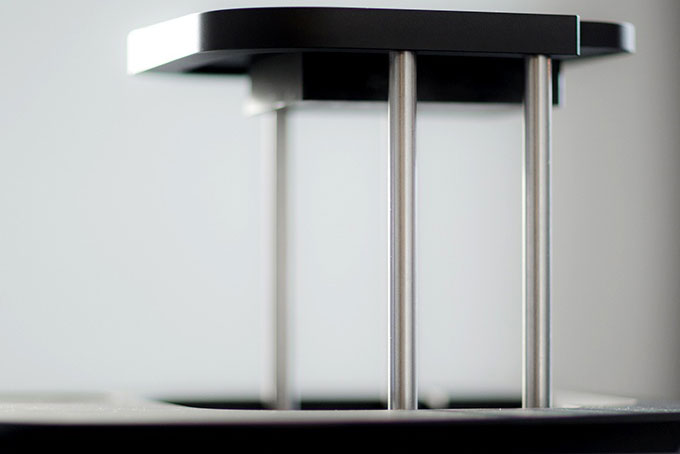

Unlike conventional bottom-up 3D printing systems, the NX1 interposes a transparent self-lubricating film between the bottom of the resin tank, the photo-curing resin, and the light source. By gradually releasing a layer of oil, the printer enables the finished resin to solidify while suspended on the substrate. This technique, which Nexa3D calls self-Lubricant Sublayer Photocuring (LSPc), basically removes the need to create objects layer by layer, and makes the printing process continuous instead of incremental.

If this all sounds strangely familiar, it’s probably because Nexa3D’s amazing LSPc printing technique bears a striking resemblance to the CLIP (continuous liquid interface production) technique pioneered by California startup Carbon3D — which made a splash on the Web a few months ago after appearing in a TED video.

The NX1 is still a prototype at this point, but Nexa3D says the printer is capable of printing at roughly one centimeter per minute, which is absolutely insane. With speeds like that, fabricating objects at home would ostensibly take less time than going out to a store and buying them premade. If the NX1 can live up to Nexa3D’s claims, it could very well be a game-changer for 3D printing.